Do you need help? Here Us:

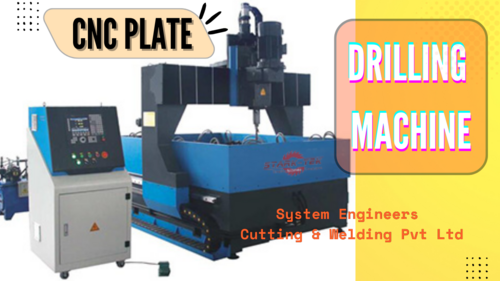

CNC Plate Drilling Machine

3500000 INR/Piece

Product Details:

- Shape Rectangular structure

- Product Type CNC Plate Drilling Machine

- General Use Industrial plate drilling

- Material Metal

- Type Drilling Machine

- Computerized Yes

- Automatic Yes

- Click to View more

X

CNC Plate Drilling Machine Price And Quantity

- 1 Piece

- 3500000 INR/Piece

CNC Plate Drilling Machine Product Specifications

- Yes

- Industrial plate drilling

- Metal

- Provided

- CNC Plate Drilling Machine

- Yes

- CNC

- 1 Year

- Polishing

- Drilling Machine

- Rectangular structure

- Blue

- Yes

- Drilling capability for plates

Product Description

CNC Steel Plate Drilling Machine is widely used in steel frame construction.Main features:

1. High production efficiency: There are two movable worktables.

2. High precision machining: X/Y-axis is driven by AC servo motor ball screw driving system; power head and worktable are moving in a straight line rolling guide.

3. This system has powerful function and can control 5 feeding axis with high control precision.

4. Safe, reliable: when a table is loading and unloading the work-piece, the power head will not move to this area; numerical control system, electrical actuators, hydraulic components use brand-name imported parts.

5. It is equipped with automatic chip cleaner.

Advanced CNC Control System

Equipped with an intelligent CNC control system, this plate drilling machine delivers superior precision and consistent performance. The computerized interface, combined with a responsive touch screen, allows operators to execute complex drilling patterns effortlessly. The machine is ideal for repetitive industrial plate drilling, ensuring minimal errors and optimal productivity.

Efficient and Durable Construction

Constructed with a sturdy, rectangular metal frame and finished with high-quality polishing, this machine is built for longevity and heavy-duty usage. Its blue exterior gives it a modern look, while the automatic features reduce manual intervention, streamlining operations and minimizing downtime in busy factory environments.

Comprehensive Support and Warranty

As a prominent distributor, importer, manufacturer, supplier, trader, and wholesaler in India, we provide thorough after-sales service and a 1-year warranty for the CNC Plate Drilling Machine. Detailed technical drawings and user manuals are supplied, ensuring smooth installation and operation for all our customers.

FAQs of CNC Plate Drilling Machine:

Q: How does the CNC Plate Drilling Machine improve industrial drilling processes?

A: By utilizing computerized numerical control (CNC) and automatic functionality, the machine enhances accuracy, speed, and consistency when drilling metal plates, reducing manual labor and production time.Q: What materials and shapes can this machine process?

A: This drilling machine is designed to handle various metal plates with a rectangular structure, delivering precise holes and polished finishes to suit diverse industrial applications.Q: When should I schedule maintenance for the CNC Plate Drilling Machine?

A: Standard maintenance is typically recommended after every 6 months of use or as indicated by the manufacturers guidelines included in the warranty and user manual.Q: Where is this machine primarily used?

A: The CNC Plate Drilling Machine is mainly utilized in industrial fabrication facilities, metalworking plants, and manufacturing units all over India that require precise and efficient plate drilling.Q: What is the installation process for this machine?

A: Installation is simplified with provided technical drawings and user manuals. Typically, a qualified technician will set up the machine, connect the CNC system, and perform initial calibrations.Q: How do operators use the touch screen and control system?

A: Operators access the intuitive touch screen to input drilling patterns and parameters; the CNC control system then executes the programmed operations with minimal supervision.Q: What are the key benefits of using this CNC Plate Drilling Machine?

A: Users benefit from automated, high-precision drilling, improved workplace efficiency, reduced operator errors, and professional results, all reinforced by a 1-year comprehensive warranty.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'PEB Fabrication Machine' category

We aim to be the best CNC Plasma Cutting Machine Supplier, Hypertherm Plasma System Supplier and PEB Machineries Supplier throughout all India, Our Sales & Marketing Offices are in Faridabad, Amritsar, Ludhiana, Bangalore, Hyderabad, Raipur, Nagpur & Chennai.

|

SYSTEM ENGINEERS CUTTING & WELDING PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |