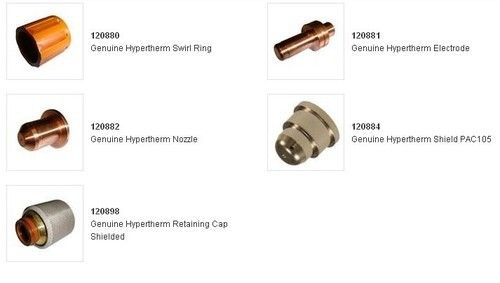

Hypertherm Plasma Consumables

Product Details:

- Usage Industrial

- Type Hypertherm Plasma Consumables

- Condition New

- Size Standard

- Material Metal, Copper

- Color Golden

- Click to View more

Hypertherm Plasma Consumables Price And Quantity

- 10 , , Unit

- 600.00 - 1800.00 INR/Unit

Hypertherm Plasma Consumables Product Specifications

- Standard

- New

- Metal, Copper

- Hypertherm Plasma Consumables

- Golden

- Industrial

Hypertherm Plasma Consumables Trade Information

- 10-15 , , Unit Per Day

- 1 Week

Product Description

Hypertherm Consumables we deal in are provided with many latest technologies and increase the efficiency of the plasma cutting systems. Supplied consumables have been made from the highest standards and are proffered with improved cutting quality, boosted productivity, extended consumable life and others. Hypertherm Consumables are supplied with various system features and contribute to the high reliability as well as optimized performance. These proffer consistent cut quality as well as enhanced consumable life. Provided are delivered with advanced plasma technology and are the optimal cutting solutions, which ensure advanced cut quality and maximize the productivity.

Technical Parameter:

| Brand | System Engineers |

| Material | Copper |

| Type | Casting parts |

Engineered for Demanding Industrial Applications

Hypertherm Plasma Consumables are purpose-built to withstand rigorous industrial use. Crafted from high-grade metal and copper, these parts promise both durability and high conductivity, making them ideal for repetitive, heavy-duty plasma cutting operations. Their standard size ensures seamless compatibility with Hypertherm cutting systems, contributing to minimized downtime and maintenance.

Available Across Major Indian Supply Channels

Whether you are a distributor, importer, manufacturer, supplier, trader, or wholesaler, obtaining Hypertherm Plasma Consumables in India is convenient and efficient. These consumables are widely available and supported by reliable after-sales services, meaning you can keep your operations running smoothly with minimal interruption.

FAQs of Hypertherm Plasma Consumables:

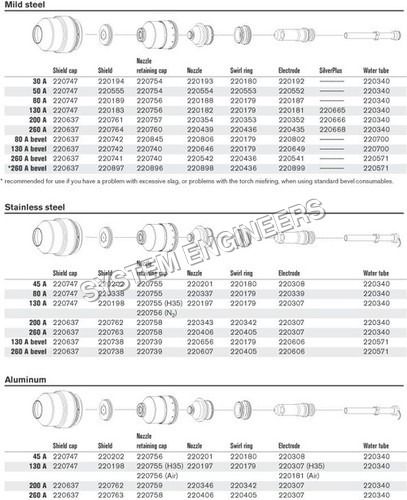

Q: How do I select the right Hypertherm Plasma Consumables for my cutting system?

A: Choosing the correct consumables involves matching your plasma cutters specificationsensure compatibility by checking the model and required standard size. Using genuine Hypertherm components maximizes performance and safely fits your industrial equipment.Q: What benefits do Hypertherm Plasma Consumables offer for industrial applications?

A: These consumables provide high conductivity, durability, and consistent cutting quality due to their premium metal and copper construction. Their precise engineering reduces the frequency of replacements, thus lowering maintenance costs over time.Q: When should Hypertherm Plasma Consumables be replaced?

A: Its recommended to replace consumables when you notice a decline in cut quality, increased spatter, or prolonged cutting response. Regular inspection of your cutting tips, electrodes, and nozzles helps maintain cutting efficiency and precision.Q: Where can I purchase Hypertherm Plasma Consumables in India?

A: You can buy these consumables through authorized distributors, importers, suppliers, manufacturers, traders, and wholesalers across India. Opt for official channels to ensure you receive genuine, new components with full manufacturer support.Q: What is the process for installing Hypertherm Plasma Consumables?

A: Before installation, ensure your cutting machine is powered down and cooled. Follow the manufacturers instructions to securely replace worn parts with new Hypertherm consumables, ensuring a proper fit to avoid operational issues.Q: How are Hypertherm Plasma Consumables typically used in industrial settings?

A: These consumables are used in plasma cutting systems for tasks such as metal fabrication, automotive work, and construction. Their robust construction enables reliable operation, enhancing output and ensuring cleaner, more accurate cuts.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Hypertherm Plasma Consumables' category

|

SYSTEM ENGINEERS CUTTING & WELDING PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |