Do you need help? Here Us:

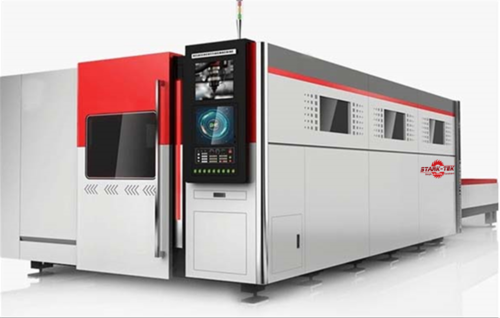

Fiber Laser Plate Profile cutting Machine

2500000.00 - 7000000.00 INR/Unit

Product Details:

- Laser Type Fiber Laser

- Material Metal

- Cutting Thickness 4mm - 16mm Millimeter (mm)

- CNC Or Not CNC

- Computerized Yes

- Cooling Mode Water Cooling

- Voltage 415 Volt (v)

- Click to View more

X

Fiber Laser Plate Profile cutting Machine Price And Quantity

- 2500000.00 - 7000000.00 INR/Unit

- 1 Set

Fiber Laser Plate Profile cutting Machine Product Specifications

- Fiber Laser

- CNC

- 4mm - 16mm Millimeter (mm)

- Yes

- 8000 Kilograms (kg)

- High Performance, Low Noise, Lower Energy Consumption, Simple Control

- Metal

- 415 Volt (v)

- Water Cooling

Fiber Laser Plate Profile cutting Machine Trade Information

- 10-15 Set Per Month

- 1 Months

- All India

Product Description

Technical specification|

Model |

Specifications |

|

Max cutting range |

3000mm x 1500mm |

|

Cooling way |

Water cooling |

|

Laser wave length |

1070nm |

|

Laser output power |

2000W |

|

Laser input power |

10KW |

|

Min line width |

0.15mm |

|

Cutting depth |

0.2-10mm |

|

Driving way |

Imported servo motor |

|

Tranmission way |

Y-axis importe gear rack double driver,X-axis imported ball screw |

|

Power requirements |

415V/50HZ |

|

Environment temperature |

5-35 C |

|

Continous working time |

24 hours |

|

Weight of the machine |

8000 kg |

|

Outline size |

8500mm x 2900mm x 2100mm (length x width x height) |

Precise and Efficient Metal Processing

This machine is tailored for cutting metal plates with exceptional accuracy across various thicknesses. The integration of high-powered fiber laser technology ensures clean edges and intricate shapes while maintaining minimal thermal distortion. Its advanced capabilities optimize workflow and improve productivity in fabrication projects.

User-Friendly CNC Control

With full CNC automation and intuitive computerized controls, the machine enables operators to manage cutting parameters efficiently. Its simple control interface makes it accessible for both skilled technicians and new users, streamlining setup and production cycles while minimizing potential errors.

Energy-Efficient and Durable Design

Engineered with a focus on energy savings and longevity, the fiber laser cutting machine features lower energy consumption compared to traditional cutting equipment. The robust metal construction and effective water cooling system add to its durability, making it a reliable asset for demanding industrial environments.

FAQs of Fiber Laser Plate Profile cutting Machine:

Q: How does the fiber laser plate profile cutting machine operate?

A: This machine utilizes fiber laser technology combined with computerized CNC controls to execute precise cuts on metal plates. Operators input the cutting design into the control system, which guides the laser for accurate profiling based on programmed specifications.Q: What materials and thicknesses can this machine cut?

A: Designed for metal materials, the machine efficiently handles plate thicknesses ranging from 4mm to 16mm, making it suitable for a wide array of industrial applications requiring metal processing.Q: When is fiber laser cutting most advantageous over other cutting methods?

A: Fiber laser cutting offers superior precision, minimal maintenance, reduced energy costs, and lower operational noise. It is particularly advantageous for projects requiring clean, complex cuts in metals, especially when high productivity and quality are prioritized.Q: Where is this fiber laser cutting machine commonly used in India?

A: This cutting machine is widely adopted across manufacturing plants, fabrication workshops, and metal processing units throughout India. Its availability through distributors, importers, manufacturers, suppliers, traders, and wholesalers makes it accessible nationwide.Q: What is the process of setting up and operating the CNC function?

A: Setup involves connecting the machine to a 415-volt power supply and water cooling system. Operators load the cutting design into the computer interface, configure the settings for material type and thickness, and then the CNC system automates the cutting process with high precision.Q: How do users benefit from the high performance and low noise features?

A: High performance ensures fast, accurate cuts leading to increased productivity, while the low noise operation creates a safer and more comfortable working environment for operators, improving overall workplace efficiency.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in ' CNC Laser Cutting Machine' category

We aim to be the best CNC Plasma Cutting Machine Supplier, Hypertherm Plasma System Supplier and PEB Machineries Supplier throughout all India, Our Sales & Marketing Offices are in Faridabad, Amritsar, Ludhiana, Bangalore, Hyderabad, Raipur, Nagpur & Chennai.

|

SYSTEM ENGINEERS CUTTING & WELDING PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |