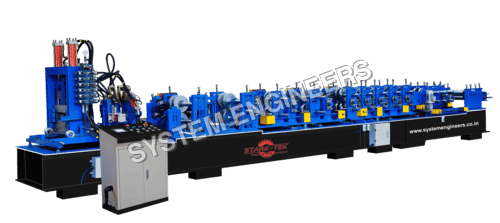

Automatic Decking Sheet Forming Machine

Product Details:

- Type Automatic Decking Sheet Forming Machine

- Material Steel

- Computerized No

- Automatic Grade Semi-Automatic

- Voltage 220 Volt (v)

- Color Blue

- Warranty Yes

- Click to View more

Automatic Decking Sheet Forming Machine Price And Quantity

- 1 Unit

- 600000.00 - 6000000.00 INR/Unit

Automatic Decking Sheet Forming Machine Product Specifications

- Blue

- Yes

- 220 Volt (v)

- Automatic Decking Sheet Forming Machine

- Semi-Automatic

- Steel

- No

Automatic Decking Sheet Forming Machine Trade Information

- 10-15 Unit Per Week

- 1 Months

- As per Requirement

- All India

Product Description

DECKING SHEET FORMING MACHINE

Introduction

Model WLFM55-208-832 series decking forming machine consists of uncoiler and its base, coil sheet guiding equipment, roll forming system, post-cutting equipment, hydraulic station, controlling system, supporter table. The corrugated profile sheet produced by this machine has high strength with big rib, which adheres well to concrete. Its best to be used as the floor of high buildings.

Technical Specifications

| Material Spec | Galvanized steel sheet |

| Thickness of Coil Sheet | 0.8 --1.2 mm |

| Main Motor Power | 18.5kw |

| Forming Speed | 10--12m/min |

| Hydraulic Station Power | 3kw |

| Quantity of Stands | About 24 groups |

| Hydraulic Pressure | 10-12Mpa |

| Controlling System | PLC |

| Index Error of Length | 10m±2mm |

| Total Weight | About 1800kg |

| Voltage | 380V 3 phase 60Hz or to the buyer's requirement |

Features

High solid forming stand guarantees the stable forming and uniform high quality of final products. Able to secure higher productivity since the management of the line is automated by controlling an electronic system. Improved cutting method minimizes the tolerance of cutting length.

Enhanced Productivity with Semi-Automatic Efficiency

This decking sheet forming machine delivers fast, consistent sheet production while maintaining operational simplicity. Its semi-automatic grade enables smoother workflow transitions, maximizing output without complex computerized interfaces. The sturdy steel construction ensures extended durability, making it a preferred option for businesses aiming to scale their sheet manufacturing capabilities.

Versatility Backed by Reliable Support

Available through a wide network of distributors, manufacturers, and wholesalers across India, this machine addresses the demands of various industries. The inclusive warranty brings peace of mind, while support from experienced suppliers facilitates smoother installation, training, and maintenance throughout the product lifecycle.

FAQs of Automatic Decking Sheet Forming Machine:

Q: How does the Automatic Decking Sheet Forming Machine operate?

A: The machine works by feeding steel material through a set of precision rollers to form decking sheets automatically. Operators guide and manage input materials, while the semi-automatic design ensures efficient output without requiring advanced computer programming.Q: What are the main benefits of using this decking sheet forming machine?

A: Key benefits include reliable high-volume production, enhanced durability due to steel construction, and straightforward operation that does not require specialized technical skills. Its semi-automatic mode strikes a balance between automation and control, boosting productivity on the shop floor.Q: When is the optimal time to use this machine in the production process?

A: This machine is best utilized during the sheet forming phase of construction or manufacturing projects, once steel material is ready for processing. It helps meet project timelines by producing decking profiles swiftly and in large volumes.Q: Where can I buy the Automatic Decking Sheet Forming Machine in India?

A: You can purchase this machine from authorized distributors, manufacturers, traders, importers, and wholesalers throughout India. Check with local suppliers for availability, or consult manufacturers for direct sales and support.Q: What is the process for installing and commissioning the machine?

A: After delivery, the machine should be installed on a stable, leveled surface. Basic electrical connections to a 220V power supply are needed. Suppliers usually offer setup assistance and guidance to help you commence operations safely and efficiently.Q: How should the machine be maintained for optimal performance?

A: Regular maintenance includes routine cleaning, inspecting rollers for wear, and ensuring all fittings are secure. Lubricate moving parts as per the manual and schedule periodic checks with your supplier to prolong machine life.Q: What warranty and after-sales support are available?

A: This machine comes with a warranty that covers certain mechanical and operational aspects. For detailed terms, consult the distributor or manufacturer from whom you purchase. Most suppliers also provide after-sales support for training and troubleshooting.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Roll Forming Machine' category

|

SYSTEM ENGINEERS CUTTING & WELDING PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |