Automatic Z Purlin Roll Forming Machine

Product Details:

- Computerized No

- Automatic Grade Semi-Automatic

- Control System PLC Control

- Voltage 415 Volt (v)

- Weight 13000 Kilograms (kg)

- Click to View more

Automatic Z Purlin Roll Forming Machine Price And Quantity

- 600000.00 - 6000000.00 INR/Unit

- 1 Unit

Automatic Z Purlin Roll Forming Machine Product Specifications

- PLC Control

- 415 Volt (v)

- No

- 13000 Kilograms (kg)

- Semi-Automatic

Automatic Z Purlin Roll Forming Machine Trade Information

- 10-15 Unit Per Week

- 1 Months

- All India

Product Description

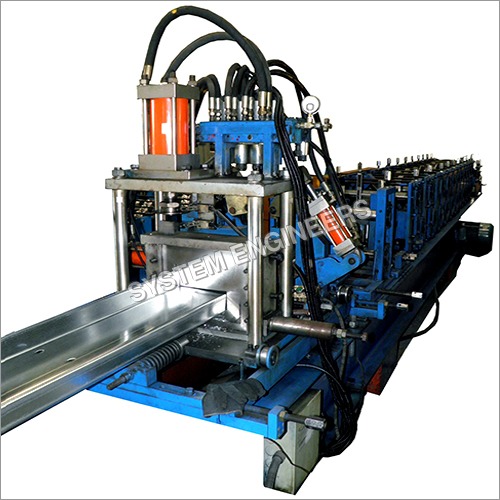

Z Purlin Roll Forming Machine

Z Purlin Roll Forming Machine, offered by System Engineers Cutting & Welding Pvt. Ltd assist in providing high level of structural support to different sorts of buildings. This is accessible in various sizes and has PLC for improved performance. Additionally, it ensures high reliability in various conditions. Z Purlin Roll Forming Machine is made from scratch-less material and ensures advanced precision. This durable machine is helpful in making door frame, beam panels, glass wool panel profiles, pallet racks, pack post and different others.

Product Details:

| Automatic Grade | Automatic |

| Weight | About 13,000kg |

| Controlling system | PLC |

| Working speed | 8000-10000 mm/min |

| Product range | All the types from 100 to 250 |

| Quantity of Stands | About 16 groups |

| Material of roller die | Bearing steel with quenched treatment. |

Features:

- Simple yet reliable operations

- Low operating cost in comparison to others

- Serves the purpose

Efficient Z-Purlin Production

This roll forming machine specializes in producing Z-profile purlins, which are vital structural elements in steel-framed buildings. Its semi-automatic operation ensures reliable output consistency, offering flexibility for operators to adjust parameters as needed. The robust design and heavy-duty frame support sustained industrial use.

Simple PLC Control System

With an integrated PLC (Programmable Logic Controller) system, the machine streamlines processes and minimizes errors. While it is not computerized, the PLC interface allows operators to manage settings efficiently, optimizing throughput without demanding complex technical skills.

Wide Distribution Across India

Our machine is accessible across India, catering to the needs of various stakeholders including importers, manufacturers, suppliers, and wholesalers. It is supported by a network that guarantees timely delivery, after-sales assistance, and availability of spare parts.

FAQs of Automatic Z Purlin Roll Forming Machine:

Q: How does the Automatic Z Purlin Roll Forming Machine operate?

A: The machine utilizes a PLC control system to manage the semi-automatic roll forming process. Operators input production parameters, and the machine forms Z-shaped purlins from metal coils, requiring occasional manual adjustments.Q: What are the benefits of using this semi-automatic machine for Z purlin production?

A: This machine offers a balance between efficiency and flexibility, enabling consistent quality output while allowing operators to intervene as necessary. Its robust frame and PLC control ensure durability and reliable production cycles.Q: Where can this Z purlin roll forming machine be sourced in India?

A: It is available through multiple channels across India, including distributors, importers, manufacturers, suppliers, traders, and wholesalers. Support and service networks ensure smooth procurement and maintenance.Q: When is this machine most suitable for use?

A: The machine is best suited for industrial settings with medium to high production demands, particularly for those specializing in steel construction components such as Z purlins.Q: What is the typical process flow when using the machine?

A: The process begins by feeding metal coils into the machine, after which the rolling stations shape them into Z profiles under PLC control. Cut lengths are produced as per the set parameters, ready for further assembly.Q: How is the machine maintained to ensure optimal performance?

A: Routine inspections, timely lubrication, and adherence to the manufacturers maintenance schedule are required. The availability of spare parts through the supplier network in India aids in minimizing downtime.Q: What are the primary usage areas of the Z purlins produced by this machine?

A: Z purlins manufactured with this machine are commonly used as structural supports in steel-framed buildings, warehouses, industrial sheds, and pre-engineered constructions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Roll Forming Machine' category

|

SYSTEM ENGINEERS CUTTING & WELDING PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |